Program To Design A Pad Eye Type Lifting Lug V.02

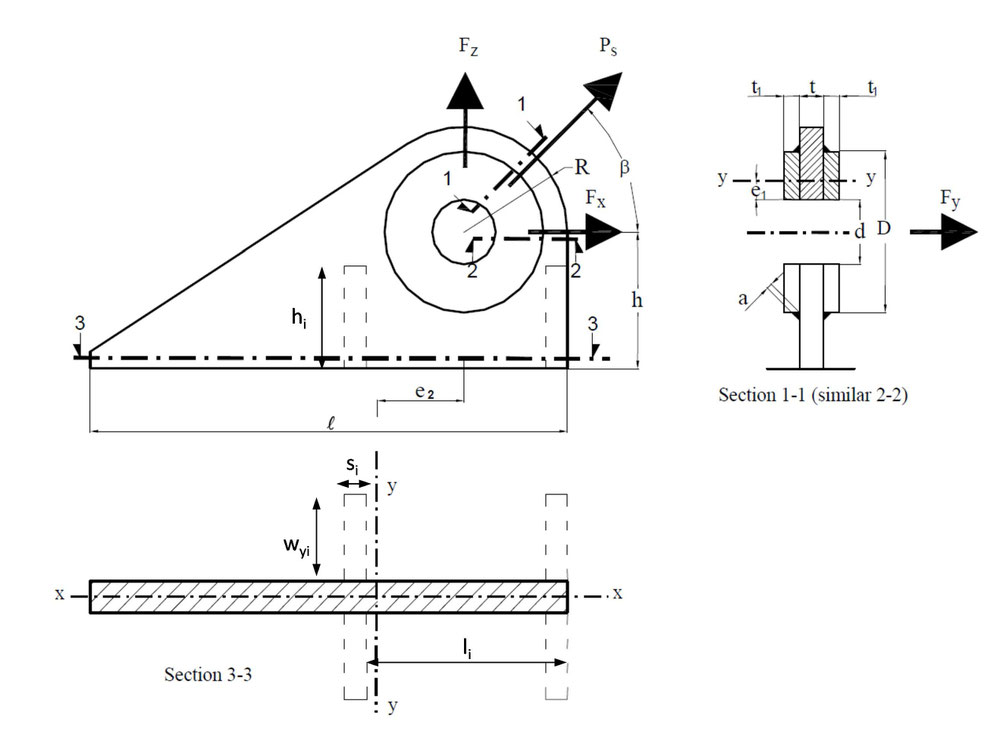

For any manufactured equipment, the geometry of the padeye must match the size of shackle to be used to ensure a rated connection between the equipment and the lifting set.

Absolute power exercise physiology. DNV states two key sizing rules which are of importance:

One lug program designs pad eye type lifting lugs and the other one designs plate type lifting lugs. PROGRAM TO DESIGN A PLATE TYPE LIFTING LUG v.03. Select a metric shackle from the lookup table based on the force on the lug or click the SHACKLE button to enter. Download atdi ics telecom cracker. ATDI offer a new generation of software to the. Oct 28, 2015 MSI LIFTING LUG & PAD EYE DESIGN GUIDELINES. Dated: 28th Feb 2002. Design Consideration for Lifting Point 3. Pad Eye Design Appendix A Example: Pad Eye Detail based on APEA, Guideline for Lifting Equipment. Appendix B Example: Shackle Crosby Bow and Dee Type. MSI LIFTING LUG / PAD EYES DESIGN GUIDELINES. One lug program designs pad eye type lifting lugs and the other one designs plate type lifting lugs. PROGRAM TO DESIGN A PLATE TYPE LIFTING LUG v.03. Select a metric shackle from the lookup table based on the force on the lug or click the SHACKLE button to enter. Download atdi ics telecom cracker. ATDI offer a new generation of software to the.

- The diameter of the holes in the padeye shall match the shackle used, clearance between shackle pin and padeye hole shall not exceed 6% of the shackle pin diameter.

- The thickness of the padeye at the hole shall not be less than 75% of the inside width of the joining shackle

The correct design of padeye should be selected based on the particular load application. For straight lifting angles a symmetric padeye design should be used, for a multi-point lift as in a offshore container or frame then a nonsymmetric design can be used. If required plated supports can be added to the symmetric design to increase the lateral stiffness of the padeye, useful when the padeye will be subjected to dynamic load angles.

For a multi-point lift it is essential that the padeyes point directly to the lift point centre to prevent lateral bending moments on the padeyes, DNV suggest a tolerances of 2.5 degrees as an allowable misalignment. download text to speech mac

The program provided above allows to compute the size of the weld leg; Despite the detailed informations I could not do it, but the explanations are complete I think (to compute a 'worst case scenario' as the LUG is supposed to lift a vessel - in that case that have orientation from horizontal to vertical (I think) so the effort on the lug. PAD EYE LUG DESIGN WITH A SIDE LOAD As design engineers, it is our responsibility to make sure that our lug designs meet the latest codes before they are issued for fabrication, but due to the variables in fabrication, installation, field implementation, etc, the designs might not fit right or be used right to code. JUNE 23RD, 2018 - PROGRAM TO DESIGN A PAD EYE TYPE LIFTING LUG V 02 TABLE BASED ON THE FORCE ON THE LUG OR CLICK THE SHACKLE LUG RADIUS USED TO CALCULATE THE MAX' 'Lifting Lug Design Spreadsheet Kezar Engineering June 23rd, 2018 - Among the methods available to calculate the lifting lugs With. Lifting Padeye 7 2.2 Load out of Main support frame 2012 7 2.3 Padeye for vessel lifting 10 2.4 Vertical lifting of vessel using lifting lug 10 2.5 Padeyes used in the lifting of ship component 12 2.6 Padeyes used in the lifting of ship Bridge 12 2.7 Padeye checks based on GLND Guideline for Marine Operation 20 2.8 MPI on lifting lug.

For padeyes rated above 2000kg capacity cheek plates must be fitted to reduce the play in the shackle-padeye connection. These must be fitted as additional plates welded onto the padeye profile and not a single boss as shown below.

Padeye Materials

For equipment used in a marine environment, all padeye materials are to be S335J2 (BS EN 10025) supplied with 3.1 material inspection certificates to BS EN 10204.

Padeye Welding

All padeyes must be welded to the primary struture by use of full penetration welds. It is good practure to extend the base of the padeye to pass it completely through the structural member which it is connected to. /titanic-dubbed-in-hindi-full-movie-download.html. If welding directly onto horizontal plate then the plate must be specified as EMZ grade to prevent delamination of the plate under tensile load.

When sizing the correct padeye for your application consider the following:

- Maximum foreseen gross load

- Load test requirements

- Dynamic amplification factor (DAF)

- Drag load on equipment when lifting through water

- Potential captured water weight when lifting equipment out of water

This document has been created as a guide and should not be used as a substitute to correct design calculations. All lifting frames including padeye design should be checked by calculation and ideally independently checked and approved prior to manufacturing. Post manufacture load testing must be performed prior to equipment use.

For a complete dimensional overview of standard padeye designs please click below: